China Manufacturer of Color Masterbatch & Additive Masterbatch|ZINUO

- +86-183-3638-0907

- info@znmasterbatch.com

Additive Masterbatch

Aadditive masterbatch is a concentrated mixture of one or more additives (like chemicals or powders) encapsulated within a carrier resin. It is a solid, pellet-shaped product designed to be diluted into a base polymer (like PE, PP, PS, etc.) during the plastics manufacturing process. Using masterbatch is far more efficient, cleaner, and consistent than handling raw additives directly.

Features of Additive Masterbatch

- Additive Masterbatches convert messy powders, sticky liquids, or hazardous raw additives into clean, dust-free, and easy-to-handle pellets. This improves workplace safety and housekeeping.

- The pre dispersed nature of additives in a carrier resin ensures accurate feeding and weighing, leading to a homogenous distribution of the additive throughout the final product.

- Additives like lubricants and processing aids improve polymer flow, reducing cycle times in injection molding and increasing line speeds in extrusion.

- Additives like UV stabilizers and antioxidants protect the plastic from environmental degradation, making the product last longer.

- Provides excellent color consistency, gloss/matte control, and eliminates surface defects like bubbles or streaks.

Masterbatch Catalog

Additive Masterbatch

Anti-Static Masterbatch

Reduces the surface resistivity of plastics, preventing the buildup of static electrical charges. This minimizes dust attraction and the risk of electrostatic discharge (ESD) that can damage sensitive electronics.

Slip Masterbatch

Prevents plastic films from sticking together (blocking), ensuring they can be separated easily.Reduces the coefficient of friction, improving the lubricity of film surfaces.

Flame Retardant Masterbatch

Suppresses or delays the combustion process of plastics, reducing the flame spread rate, and in many cases, causing the material to self-extinguish.

Antibacterial Masterbatch

Reduces the surface resistivity of plastics, preventing the buildup of static electrical charges. This minimizes dust attraction and the risk of electrostatic discharge (ESD) that can damage sensitive electronics.

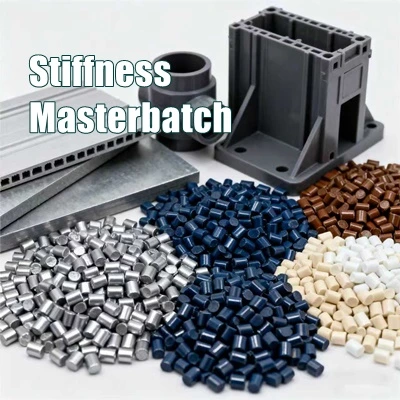

Stiffness Masterbatch

Significantly increases the flexural modulus and rigidity of the polymer, improving hardness and heat deflection temperature (HDT). Reduces part warpage.

Anti Impact Masterbatch

Significantly enhances the toughness and durability of plastic products by improving their resistance to cracking and breaking under physical impact or stress.

Transparency Masterbatch

Promotes the formation of a finer crystal structure in semi-crystalline polymers (like PP), thereby reducing haze and significantly increasing clarity, gloss, and transparency.

Anti-Rust Masterbatch

Protects metal components or inserts embedded in or in contact with the plastic part from oxidation and corrosion. Forms a protective barrier or releases vapor-phase inhibitors

Anti-Fog Masterbatch

Prevents the formation of tiny fogging on the inner surface of plastic films or packaging. It works by modifying the surface tension, causing moisture to spread into a continuous, transparent layer of water instead of discrete droplets, thereby maintaining clarity and visibility.

GET IN TOUCH