China Manufacturer of Color Masterbatch & Additive Masterbatch|ZINUO

- +86-183-3638-0907

- info@znmasterbatch.com

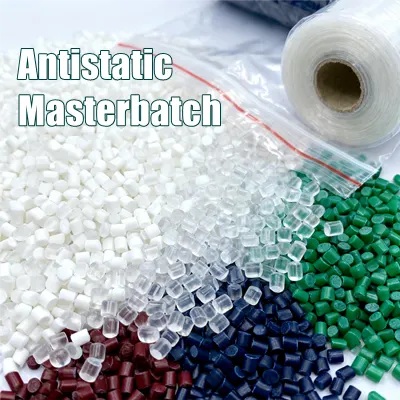

Anti Static Masterbatch

ZINUO Anti-Static Masterbatch prevents static electricity in plastics. Eliminate dust attraction, prevent ESD damage to electronics, and ensure safer handling. Custom solutions for PP, PE, ABS and more.

Introduction of Antistatic Masterbatch

- ZINUO's Anti Static Masterbatch is a high performance additive that provides permanent or static protection to plastic products. By integrating it directly into polymer during production, you can solve the persistent problems caused by static electricity, ensuring cleaner, safer, and reliable products.

- Our masterbatch is compounded with specialized agents that creating a conductive path on the surface of the plastic. This allows static charges to dissipate safely and continuously, rather than building up. We offer different formulations to meet your needs

- For manufacturers, using Anti-Static Masterbatch is a strategic decision that directly impacts product quality, production efficiency, safety, and costs.

- Plastic trays, reels, tubes, and foam used in the manufacturing, testing, and shipping of everything from smartphones and laptops to automotive control units and medical devices.

Masterbatch Catalog

Features and Application of Antistatic Masterbatch

| Industry | Applied Product | Impact on Product Quality |

|---|---|---|

| Electronics & Semiconductor | Plants producing circuit boards, hard drives, chips, and electronic components. In the plastic trays, reels, boxes, and foam that hold these sensitive parts during production, testing, and shipping. | A static shock too small for a human to feel can instantly destroy a microchip. Using anti-static plastics eliminates costly electrostatic discharge failures, ensuring components function correctly and have a long lifespan. By preventing ESD damage, factories see a direct improvement in their yield and a significant drop in product returns and warranty claims. |

| Packaging for Sensitive Goods | Manufacturers of pharmaceutical, food, and high purity chemical packaging. Include bottles, containers, and flexible films that package powders, tablets, and sterile goods. | Static acts like a magnet for dust, lint, and fibers. Anti static packaging keeps the product pure, meeting strict hygiene and safety standards. This is critical for maintaining brand reputation and consumer trust. |

| Automotive & Industrial Components | Components like fuel filters, sensor housings, and under-the-hood covers. | Static can interfere with sensitive sensors and electronics in modern vehicles. In fuel systems, a static spark is a fire hazard. Using anti-static plastics prevents malfunctions and mitigates explosion risks, leading to safer, more reliable end-products. |

| Clean Room & Medical | Equipment housings, surgical tool trays, and medical device packaging. | Maintains a sterile, particle-free environment. |

| Material Handling & Logistics | Conveyor belts, storage bins, totes, and bulk containers. Integrated into the plastic of equipment that moves or stores materials, especially powders or granules. | Static causes materials to cling to container walls and belts, leading to blockages, uneven flow, and product waste. Anti-static masterbatch ensures smooth, uninterrupted production, reducing downtime and material loss. |

FAQ

What Problem Does Antistatic Masterbatch Solve?

The blow film process itself generates static electricity through friction as the film stretches, cools, and moves over rollers.

Static charge makes layers of film cling together and it causes jams on automatic bag making, printing, and packaging lines, resulting in machine downtime and lost productivity.

The static electricity film acts like a magnet, attracting airborne dust, lint, and debris from the factory environment. This contaminates the film surface, leading to a high number of rejects and quality complaints.

Static causes the film to repel or cling to machinery guides and rollers, resulting in uneven, loose, or wrinkled rolls. This makes the film difficult to handle and process in subsequent converting steps.

Why Choose ZINUO Anti-Static Masterbatch?

- Reliably reduces surface resistance to prevent static accumulation.

- Excellent dispersion ensures uniform performance in every batch.

- We help you select the right grade and dosage for your specific polymer (PP, PE, ABS, etc.) and application.

- An efficient one-step solution that adds critical functionality without complex secondary processes.

GET IN TOUCH