China Manufacturer of Color Masterbatch & Additive Masterbatch|ZINUO

- +86-183-3638-0907

- info@znmasterbatch.com

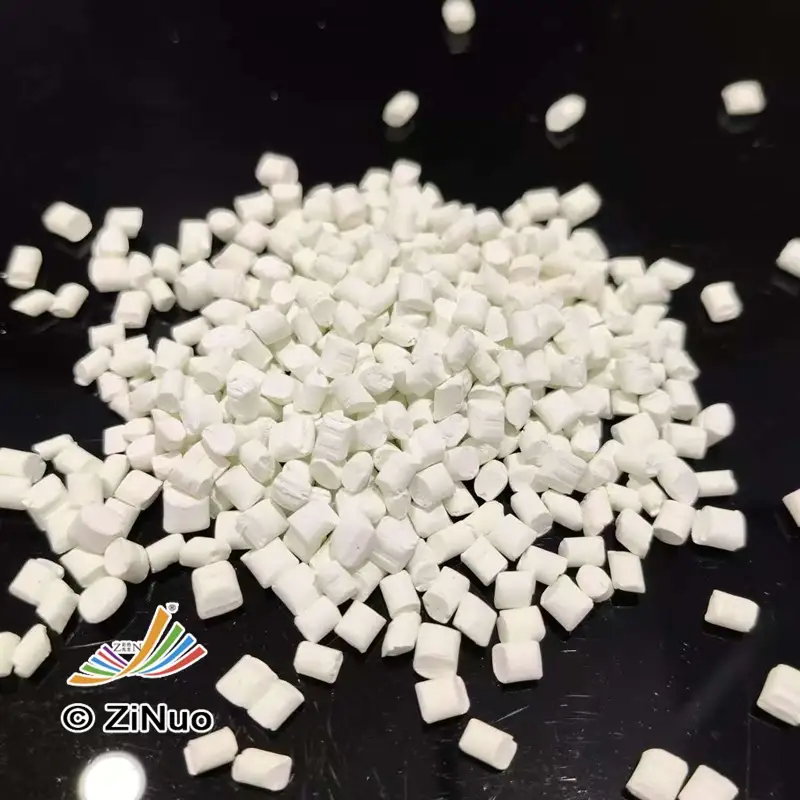

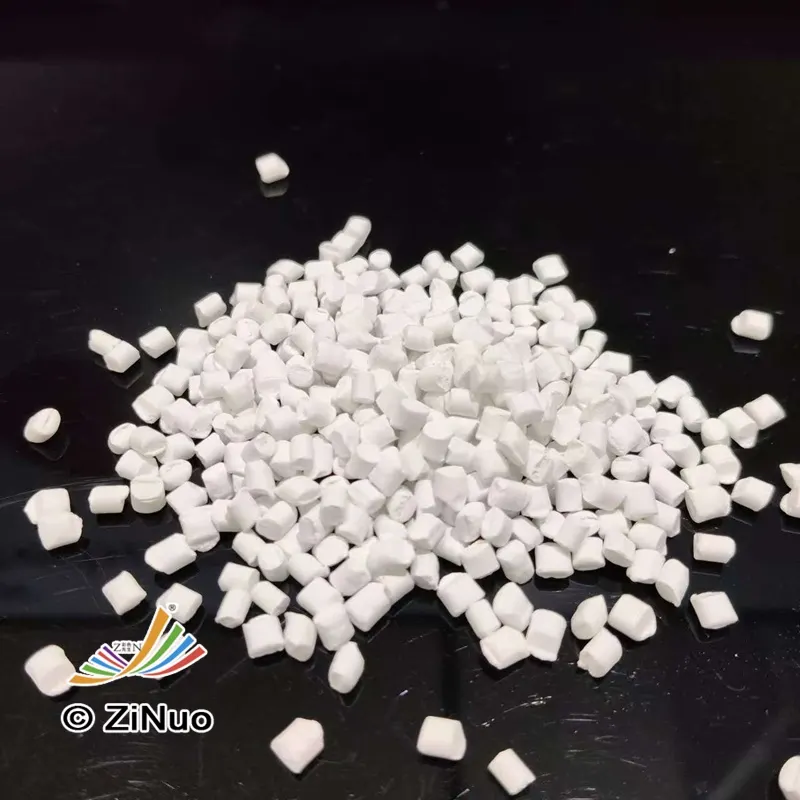

White Masterbatch

White masterbatch is a highly concentrated white pigment additive we expertly manufacture in our factory, designed to deliver consistent, brilliant opacity and color to your plastic products. As a leading masterbatch manufacturer and supplier, we produce customized solutions to meet your specific application needs.

High Opacity White Colour Masterbatch

- Superior Opacity & Whiteness: Provides excellent hiding power and a bright, consistent white color, ensuring your products look vibrant and professional.

- Engineered for even distribution within the polymer, preventing specks and ensuring a smooth, uniform surface finish.

- Our high concentration allows for lower usage rates, reducing overall material costs and improving your production efficiency.

- As a direct manufacturer, we guarantee batch-to-batch uniformity, which minimizes production disruptions and ensures reliable results every time.

- We can tailor the masterbatch to your specific application needs, including requirements for processing temperature, polymer compatibility, and end-use properties.

- ertain formulations can contribute to improved physical properties in the final product, such as increased stiffness or better UV resistance.

Masterbatch Catalog

Precision Formulation of White Masterbatch

- As the fundamental white pigment, we exclusively utilize high-purity, rutile-grade Titanium Dioxide. It is meticulously selected for its superior opacity (hiding power), which allows for thinner product walls and reduced usage rates, and its exceptional brightness, which provides a clean, vibrant base for other colors. Furthermore, we offer TiO2 grades with surface treatments that deliver enhanced weatherability and UV resistance, crucial for products exposed to sunlight and outdoor elements, thereby preventing chalking and yellowing over time.

- The carrier resin is far more than a simple pigment transporter; it is the critical link to performance. We precisely match the carrier resin to the customer's base polymer (such as Polypropylene (PP), Polyethylene (PE), Polystyrene (PS), or ABS). This ensures optimal compatibility and interfacial adhesion, which prevents issues like pigment agglomeration or surface defects. The result is a masterbatch that integrates seamlessly into the manufacturing process, ensuring excellent mechanical properties and a flawless surface finish in the final product.

- Beyond color, our white masterbatch can be engineered with a tailored additives package to become a multifunctional solution

- Dispersing Agents: To guarantee even pigment distribution and eliminate specks or streaks. Process Stabilizers: To protect the polymer during high-temperature processing, reducing degradation and maintaining material integrity. Functional Additives: Such as anti-static agents, UV stabilizers, or anti-blocking agents, which impart specific desired properties to the end-product, adding significant value beyond mere coloration.

- Process Stabilizers: To protect the polymer during high-temperature processing, reducing degradation and maintaining material integrity.

- Functional Additives: Such as anti-static agents, UV stabilizers, or anti-blocking agents, which impart specific desired properties to the end-product, adding significant value beyond mere coloration.

Wide Application of White Masterbatch

Injection Molding

Our masterbatch is formulated for excellent flowability and thermal stability, ensuring complete cavity filling in complex molds and reducing cycle times. It prevents defects like jetting or weld lines, resulting in a uniform, high-gloss surface straight from the mold.

- Thin-walled products: Food containers, lids, and caps.

- Durable goods: Housings for small appliances, power tools, and toys.

- Automotive components: Interior trim, knobs, and switch panels.

- Furniture components, casings for electronics.

Blow Molding

We prioritize melt strength and consistent parison control. Our masterbatch ensures uniform pigment dispersion, which is critical for consistent wall thickness and color in hollow products. It provides excellent surface smoothness, preventing defects and ensuring structural integrity.

- Packaging: Bottles for dairy, detergents, and personal care products, jerricans

- Large containers, drums, and automotive ducting.

- Packaging (Personal Care, Food & Beverage, Household Chemicals), Automotive, Industrial.

Film Extrusion

For film extrusion, our masterbatch is engineered for superior dispersion and low gel count. It maintains stable melt pressure, preventing screen pack clogging and ensuring consistent film thickness and excellent optical properties (clarity and gloss) in both monolayer and co-extruded structures.

- Blown Film: Shopping bags, stretch wrap, agricultural films (greenhouse films), and packaging laminates.

- Cast Film: High-clarity packaging films for food and textiles

- Key Industries Served: Flexible Packaging, Agriculture, Textile.

Sheet Extrusion

Our formulations provide exceptional surface quality and depth of color for sheets. They exhibit high heat stability to prevent degradation during subsequent thermoforming processes, ensuring color consistency even in deeply drawn areas.

- Extruded sheets for signage, sanitary ware, and interior liners.

- Thermoformed products: Yogurt cups, disposable food containers, refrigerator liners, and bathtubs.

- Key Industries Served: Packaging, Building & Construction, Advertising, Sanitary Ware.

Fiber Spinning

For this demanding process, we offer ultra-fine and thermally stable grades that prevent nozzle clogging. They ensure impeccable filtration performance and consistent coloration, resulting in strong, uniform fibers.

- Synthetic fibers for non-woven fabrics, geotextiles, carpet backing, and hygiene products.

- Key Industries Served: Textile, Geotextile, Hygiene & Medical.

- Key Industries Served: Packaging, Building & Construction, Advertising, Sanitary Ware.

Rotational Molding

Our white masterbatch for rotational molding is engineered with exceptional heat stability and fine particle size distribution. It is designed to sinter and fuse evenly within the mold during the slow heating cycle, preventing pigment agglomeration and ensuring consistent color coverage on both interior and exterior surfaces of large, hollow products

- Industrial drums and barrels

- Outdoor playground equipment and furniture

- Automotive components like fuel tanks and ducting

- Marine products such as buoys and kayaks

GET IN TOUCH