China Manufacturer of Color Masterbatch & Additive Masterbatch|ZINUO

- +86-183-3638-0907

- info@znmasterbatch.com

Color Masterbatch

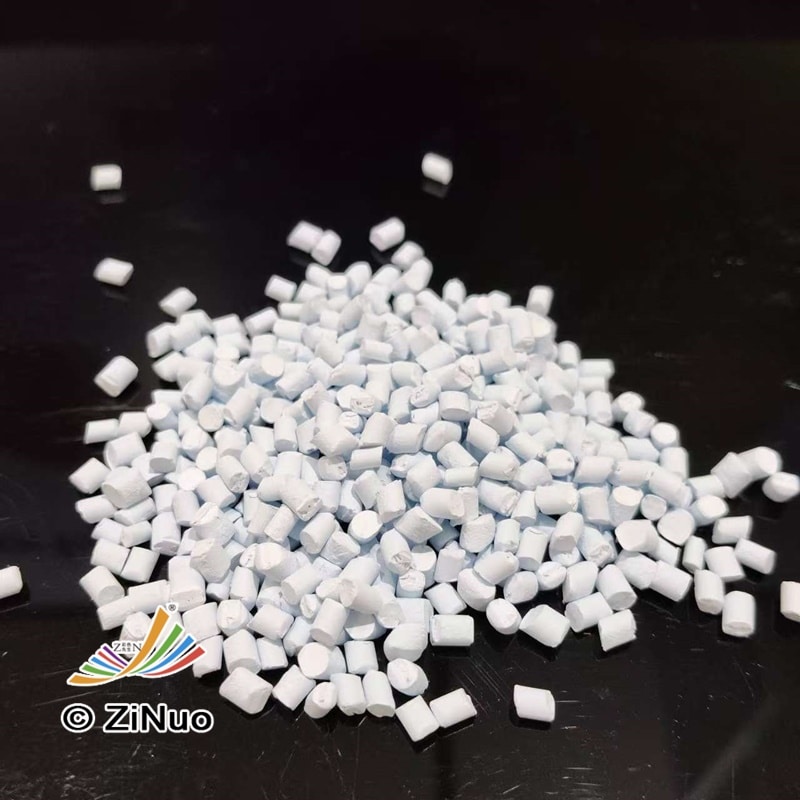

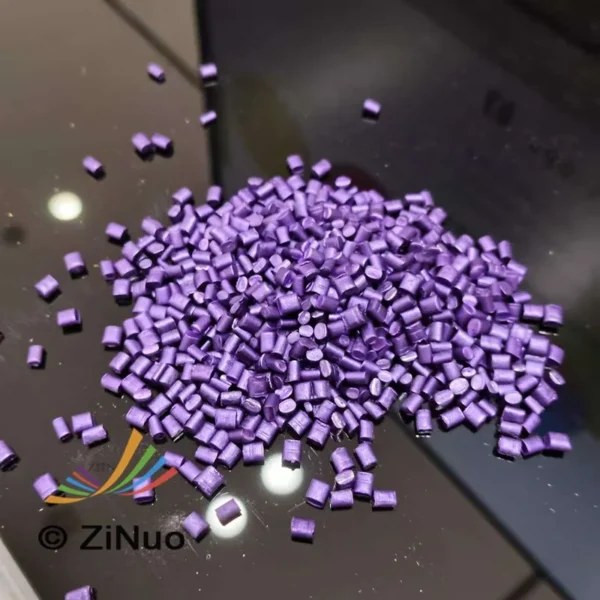

Our color masterbatch is a high-concentration formula of pigments and additives engineered within a dedicated carrier resin to deliver vibrant, consistent color across your production. We manufacturer and supply a vast spectrum of colors, from precise Pantone matches to fully custom-developed shades, ensuring your product’s exact visual requirements are met. Formulated with carrier resins like polyethylene (PE) and polypropylene (PP) for optimal compatibility, our masterbatch is ideal for applications in blow molding, injection molding, extrusion, film blown and textile fibers.

Leading Manufacturer in China

High Concentration Color Masterbatch

- Any color can be custom according to Pantone color and physical sample.

- High concentration, low dosage rate, saving cost and reducing overall material costs and improving your production efficiency.

- Guarantee excellent dispersion, No gel particles and bubble break, no bleeding.

- Good thermal resistance, no yellowing and fading during your production processing

- It can be applied to the production of plastic bags, packaging films, injection-molded parts, blow-molded containers, plastic pipes, profiles, plastic fibers, disposable tableware, electronic product casings and other plastic products.

- Perfectly compatible with PE, PP, PVC, ABS, PS, PC, PA, PET, EVA, TPR, TPE, POM, PBT and other materials, covering general plastics, engineering plastics and special plastics in full range

- Our color masterbatch is widely used in film blowing, injection molding, blow molding, extrusion, casting, thermoforming, rotational molding and other industries.

Masterbatch Catalog

- All Posts

- Color Masterbatch

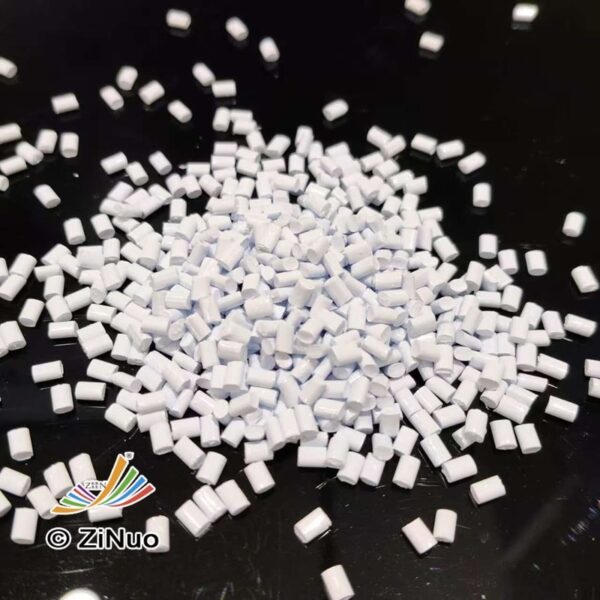

- Provides excellent hiding power and a bright, consistent white color, ensuring your products look vibrant and professional.

- Engineered for even distribution within the polymer, preventing specks and ensuring a smooth, uniform surface finish.

- Our high concentration allows for lower usage rates, reducing overall material costs and improving your production efficiency.

- As a direct manufacturer, we guarantee batch-to-batch uniformity, which minimizes production disruptions and ensures reliable results every time.

- We can tailor the masterbatch to your specific application needs, including requirements for processing temperature, polymer compatibility, and end-use properties.

- Certain formulations can contribute to improved physical properties in the final product, such as increased stiffness or better UV resistance.

Color Masterbatch Application and Product Range

Blown Film

Our color masterbatch is engineered for superior dispersion. It maintains stable melt pressure, preventing screen pack clogging and ensuring consistent film thickness and excellent optical in both monolayer and co-extruded structures.

It is widely used in the production of Carrier Bags, T-Shirt Bags, Grocery Bags, Merchandise Bags, Garbage Bags, Bin Liners, Heavy-Duty Shipping Sacks, Food Packaging Bags, Stretch Wrap, Pallet Wrap, Shrink Film, Laminating Films, Anti-Static Films, Greenhouse Films, Geo-membranes and Pond Liners, Protective Coverings

Cast Film

Our color masterbatch is specifically engineered to meet the extreme demands of the cast film industry, ensuring flawless performance and superior end-product quality. We guarantee exceptional dispersion and thermal stability to eliminate gel formation and die-lines, preventing breaks and defects in your high-speed production lines. Zinuo color masterbatch is ideal for making Stretch Wrap, Shrink Wrap, Bakery Bags, Lidding Films, Pouch Packaging for snacks, coffee, frozen food, Flow Wrap for candy bars, Window Patches on boxes, Top Sheet for Diapers and Sanitary Pads, Protective Films for screens and more.

Injection Molding

Our masterbatch is formulated for excellent flowability and thermal stability, ensuring complete cavity filling in complex molds. It prevents defects and ensure a uniform, high gloss surface straight from the mold. It is ideal for making Food containers, lids, and caps. housings for small appliances, power tools, and toys. It is also perfect to make automotive components like Interior trim, knobs, and switch panels. furniture components, casings for electronics.

Fiber Spinning

In nonwoven fabric production, color masterbatch is a fundamental raw material at the very beginning of the manufacturing process. The application is a continuous, high-speed operation designed for maximum consistency and efficiency.

Typical Products: The top and back sheets of diapers, feminine hygiene products, and adult incontinence pads. Surgical gowns, drapes, and face masks. Industrial and consumer grade colored wipes.

Sheet Extrusion

Using our color masterbatch in sheet extrusion is can help you achieving color consistency, superior thermal stability. The end products are highly visible, color is integral to the product's function, safety, and aesthetic appeal. It is widely used in packs for electronics, cosmetics, toys, yogurt cups, disposable drink cups, Transit trays for baked goods, fruits, door liners, trunk liners, Tractor hoods and body panels, Heavy truck dashboards and liners, Sanitary wall panels, Swimming pool liners and covers, Refrigerator liners and door panels and more.

Blow Molding

Our color masterbatch ensures uniform pigment dispersion, which is critical for consistent wall thickness and color in products. It provides excellent surface smoothness, preventing defects and ensuring structural integrity.

Color masterbatch are widely used in packaging industry of Personal Care, Food, Beverage, Household Chemicals, Automotive and more.

Pipe & Profile Extrusion

The use of color masterbatch in pipe and profile extrusion achieve long-term durability, consistent performance in thick sections, and cost-effectiveness. The end products are long life components for infrastructure and buildings, where color often serves a functional purpose like blue for water pipes or ensuring decades of aesthetic appeal. We offer UV stability and minimal effect on mechanical properties.

3D Printing Filament

The production of 3D printing filament is a precise form of profile extrusion. The application of color masterbatch in this process is exceptionally demanding due to the stringent requirements of the final product. Masterbatches for filament use ultra high dispersion and filtration fine pigment. Excellent thermal stability withstand the extrusion temperature. Our masterbatch is formulated not make the filament brittle.

Rotational Molding

Color masterbatch specialized in rotational molding, it is focused on achieving a uniform, speckle free color on large, complex durable hollow parts under extreme heat and low shear conditions. Such as chemical storage tanks, water tanks and fertilizer tanks, Boat fuel tanks, dockside fenders, Road barriers and traffic bollards, fuel tanks, gym equipment, playground slides and more.

GET IN TOUCH